Tenerife wildfire fighters

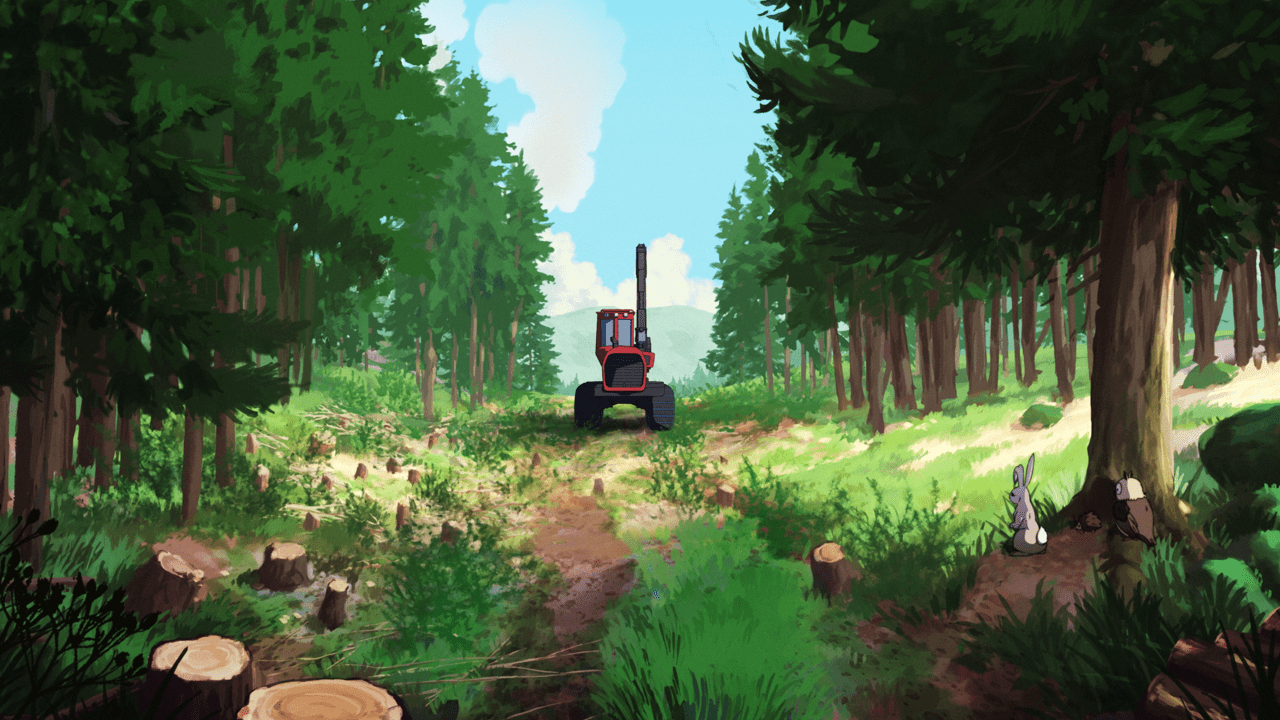

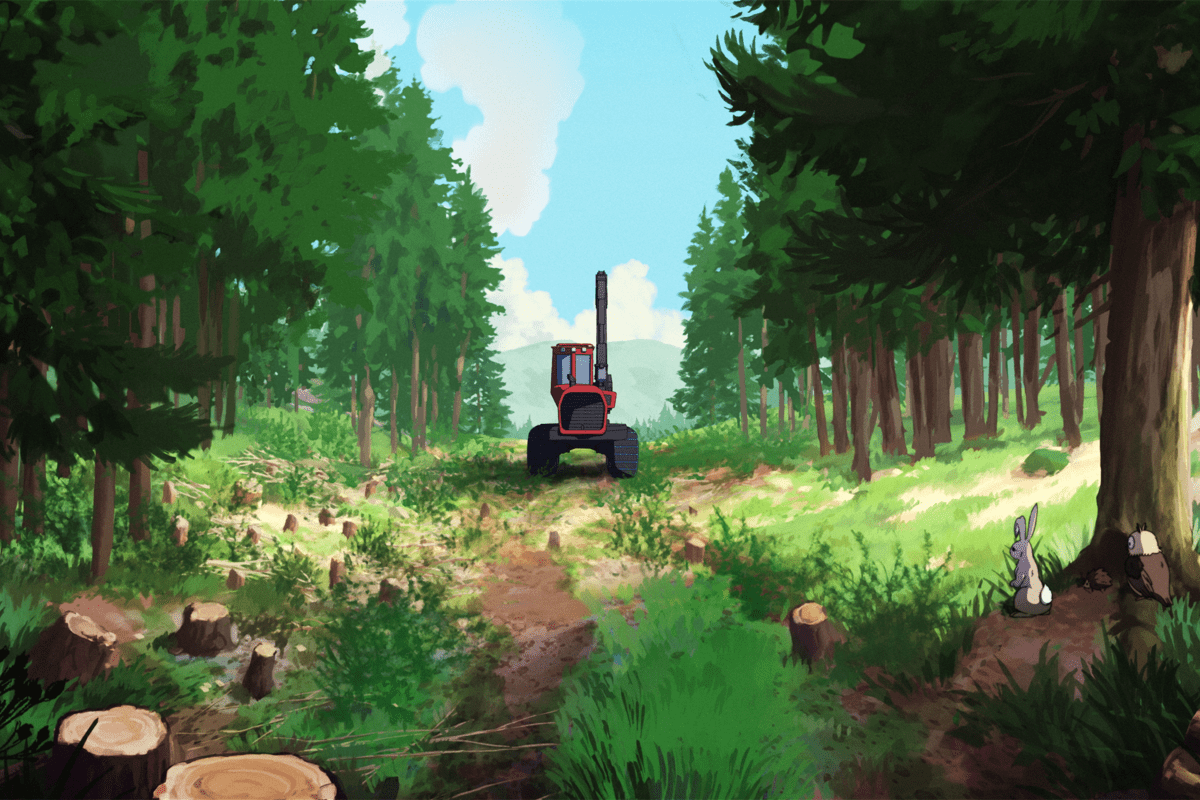

Since 2022, Komatsu’s forestry machines have played a key role in helping the local government protect Tenerifes national parks from wildfires. Thanks to the ongoing development of our smart technology, park rangers can plan the work directly from the office. Trees are marked in the field using a tablet, with precision down to the centimeter. Machine operators are able to minimize ground damage by getting the best driving routes to support forest conservation, even receiving operational updates in real time from the office.

Read more about our R&D department and how our Smart Forestry technology can help limit environmental impact while supporting vital conservation efforts.

Life in the R&D department at Komatsu

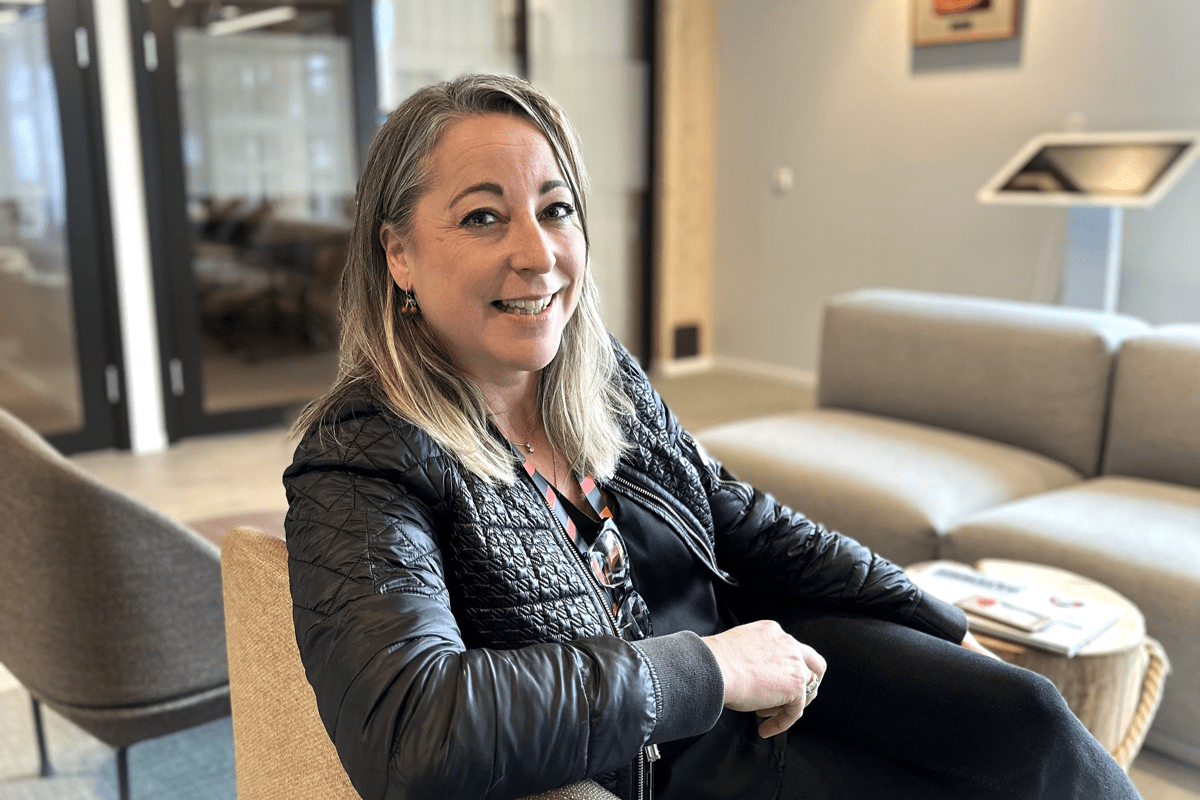

Caroline Sigge works as a project manager in one of Komatsu’s many global research and development departments. Supporting the design of forestry equipment, she manages product development teams, bringing together engineers, hydraulic experts, control system developers and mechanical designers.

Caroline Sigge, Project Manager

Engineers in the R&D department get to try ideas, test them and solve problems on the fly. It’s fast, hands-on and deeply collaborative. The work involves everything from making updates on existing machines to creating new ones from scratch.

“You’re never too new to contribute. We make decisions together, and every voice in the room matters.”

-

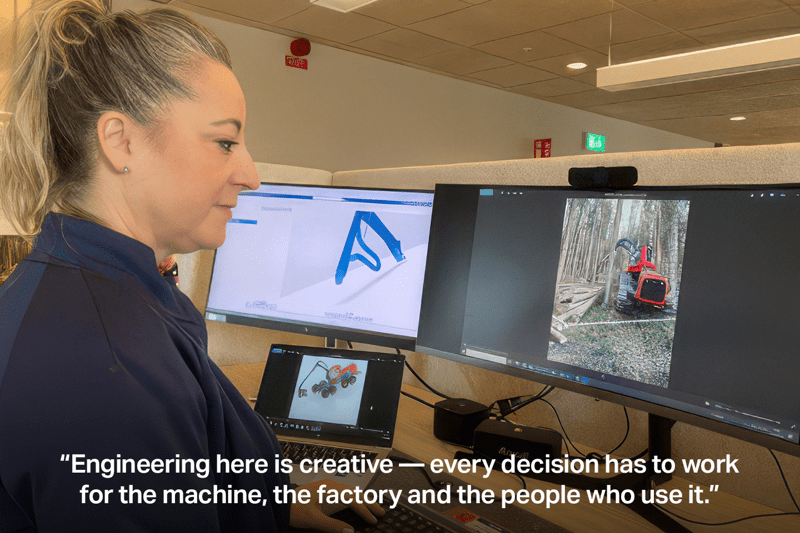

Working with Komatsu's forestry equipment means being able to adapt to any environment

The machines must operate reliably in everything from Arctic cold to Australian heat, which requires thorogh long-term durability testing under real-world conditions.

Engineers also needs to think about regional differences, like camera placement for left- vs. right-hand traffic, or whether replacement parts like hydraulic hoses are available locally. The team collaborates with global experts to ensure that every component is designes to work safely and efficiently across all target markets - from wiring and hydraulics to temeprature tolerance and visibility standards.

-

Experience the idea becoming a machine and the machine becoming a reality

If a new machine is being developed engineers get to see it go from a 3D model to something real.

Every week, designers and engineers visit the prototype workshop to look at what´s been built, talk to the people assembling it, and see how their ideas are shaping up in real metal and hydraulics.

-

True trust, responsibility, and the freedom to find our own solutions

At the R&D department, everyone is given real trust and responsibility fram early on, with the freedom to try out creative ideas and find their own solutions.

The culture encourages open communication between departments, and if one team is under preassure, others don´t hesitate to jump in. There´s always support from experienced collegues who are happy to help.

Life in the software department at Komatsu

Magnus Wallin is a software developer at Komatsu. Among other things he works on Komatsu’s Smart Forestry Vision software, a GIS-based system that provides real-time information and tools to make forestry work more efficient, precise and sustainable for everyone involved.

Magnus Wallin, Software Developer

In the software department where Magnus works, engineers work on fleet management systems and GIS-based applications that run directly on forest machines — helping operators make smarter, more sustainable decisions in the field. It’s a small, tight-knit team where developers don’t just write code — they design interfaces, prototype features, talk to real users, and see their work tested in the forests by real operators.

“We design our own wireframes, prototype new features, have our own electronics department and handle everything from front-end development to servers.”

-

Realization of software design that increases GPS accuracy to a few centimeters

One of the projects Magnus is most proud of involved software design that boosted the GPS accuracy of the machines - from a few decimeters down to just a few centimeters. This precision helps operators harvest more efficiently and reduces damage to terain by choosing the best route to drive.

The team also developed tools to support environmental regulations. Operators can now track how many high stumps they´ve left in an area - a biodiversity measure used in many countries - and recieve alerts if they get close to protected zones like cultural landmarks or conservation areas.

-

Having grown up with an interest in the outdoors, the job fit his ideal criteria

For someone who grew up hiking and caring about outdoors, the job at Komatsu ticks all the boxes for Magnus. He gets to work with a renewable resource like wood and big machines, while also helping limit their environmental impact.

To make sure every feature they develop works like it should, the team tests their software directly in the field with experienced operators and prototype drivers. These hands-on trials provide real-world insights that help catch any issues early, refine usability and ensure the tools truly support the people using them.

-

Employees who work together across departmental boundaries spend time as friends outside the office

It´s not just the mission that makes Komatsu special - it´s the people and the company culture. The team works closely, listens to each other and shares knowledge freely. They collaborate accross functions and have each other´s backs when tings get busy. And beyond the office, they have become friends - hanging out, making music and sharing more that just a workspace.

Learn more about the work to protect wildlife and natural environments through our short anime feature below.